VHP Engine Guards Redesign

VHP Engine Guards Redesign

Problem statement

Manufacturing engineers at Waukesha need a modern way to produce engine guards that meet safety requirements because their current custom welded solution creates significant operational inefficiencies and financial burden. The existing guard design on Waukesha’s VHP 12-cylinder engine family has proven to be a costly manufacturing challenge ‘custom welded fabrications require extensive labor, specialized welding expertise, and a lengthy assembly process that can bottleneck production lines. Beyond immediate cost implications, the current system’s reliance on fasteners and welded components creates potential stress concentrations and failure points in the vibration-heavy operating environment of large engines. This compromises worker safety by exposing them to dangerous rotating machinery and extreme temperatures’ a reality that weighs heavily on the minds of supervisors and project managers who are responsible for worker wellbeing. A redesigned guard system that utilizes modern manufacturing techniques such as expanded metal or laser cutting would transform this significant operational expense into a competitive advantage. These approaches could enhance worker protection by producing more reliable guards that maintain proper airflow and withstand engine vibrations. Expanded metal manufacturing offers significantly lower material waste and cost compared to plated guards [1]. This process also provides superior heat dissipation through continuous heat flow in its seamless configuration that excludes breaks and welds [1]. Laser cutting can deliver superior accuracy with minimized kerf width, reducing material waste [2]. Clean and intricate cuts also eliminate the need for extensive post-processing, further improving production speed. For Waukesha, not only will implementing the chosen solution lead to operational improvements, but it will prove to be a strategic investment that will position the company for long-term market competitiveness.

[1] Dimas Smith, Carlos Graciano, Gabriela Martinez, Expanded metal: A review of manufacturing, applications and structural performance, Volume 160, 2021, 107371, ISSN 0263-8231, https://doi.org/10.1016/j.tws.2020.107371.

Smith et al. (2021) review the production methods, typical uses, and structural behavior of expanded metal mesh materials.

[2] Naresh, Pankaj Khatak, Laser cutting technique: A literature review, Materials Today: Proceedings, Volume 56, Part 5, 2022, Pages 2484-2489, ISSN 2214-7853, https://doi.org/10.1016/j.matpr.2021.08.250.

This article outlines laser cutting applications and methodologies.

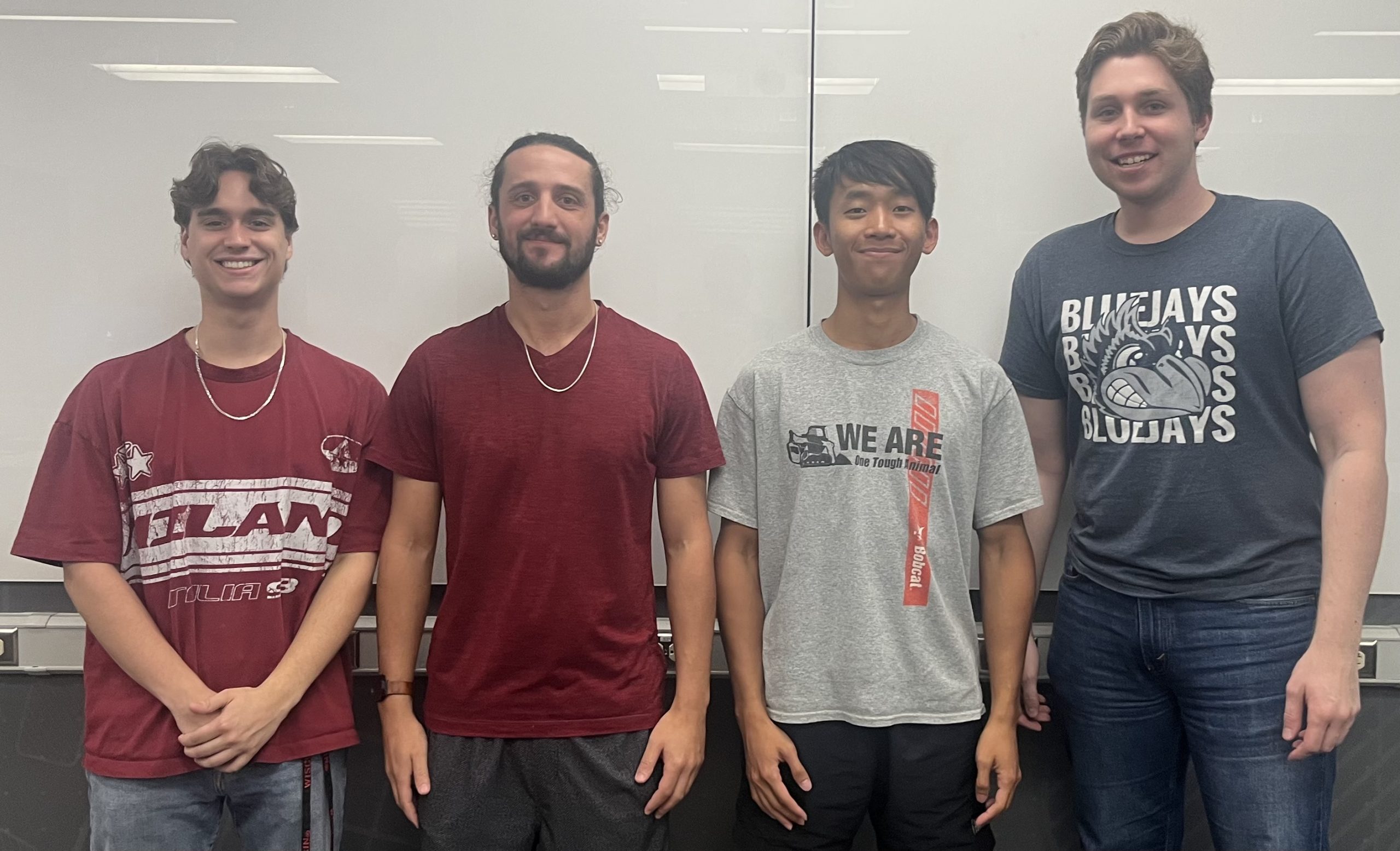

Team members

Patrick Qiu – communicator

Ryan Maccartney – admin

Maxwell Schmitz – accountant

William Nickel – facilitator

Client

Nicholas Rakovec

Innio