Preventing Microbial Growth in Draft Systems used for Non-Alcoholic Product

Preventing Microbial Growth in Draft Systems used for Non-Alcoholic Product

Problem statement

Imagine you and some of your close friends meet to have dinner and catch up with the happenings of your lives, then the following morning several of the group members become ill due to bacteria in the drinks dispensed from the restaurant’s draft system. This situation highlights a significant health and safety concern for Molson Coors: some customers are becoming sick due to harmful microbial growth in non-alcoholic (NA) beverages dispensed from draft systems [1]. This issue directly impacts consumers’ well-being, erodes trust in the brand, and places local establishments serving these beverages at risk of blame; thus, Molson Coors needs a way to control or eliminate microbial growth in the components of draft systems. The current solution to this problem requires using a chemical additive to control microbial growth [2], but the client would like to take advantage of a non-chemical solution inside the draft system. Our solution aims to take advantage of thermal, mechanical, or fluid properties to control or eliminate microbial growth, eliminating the need to use chemical additives to safely dispense beverages.

| https://iwaponline.com/ws/article/23/9/3578/96866/Microbial-contamination-analysis-of-drinking-water [1] |

| https://www.brewersassociation.org/brewing-industry-updates/caustic-line-cleaners-chemical-application-effectiveness-and-safety/Links to an external site. [2] |

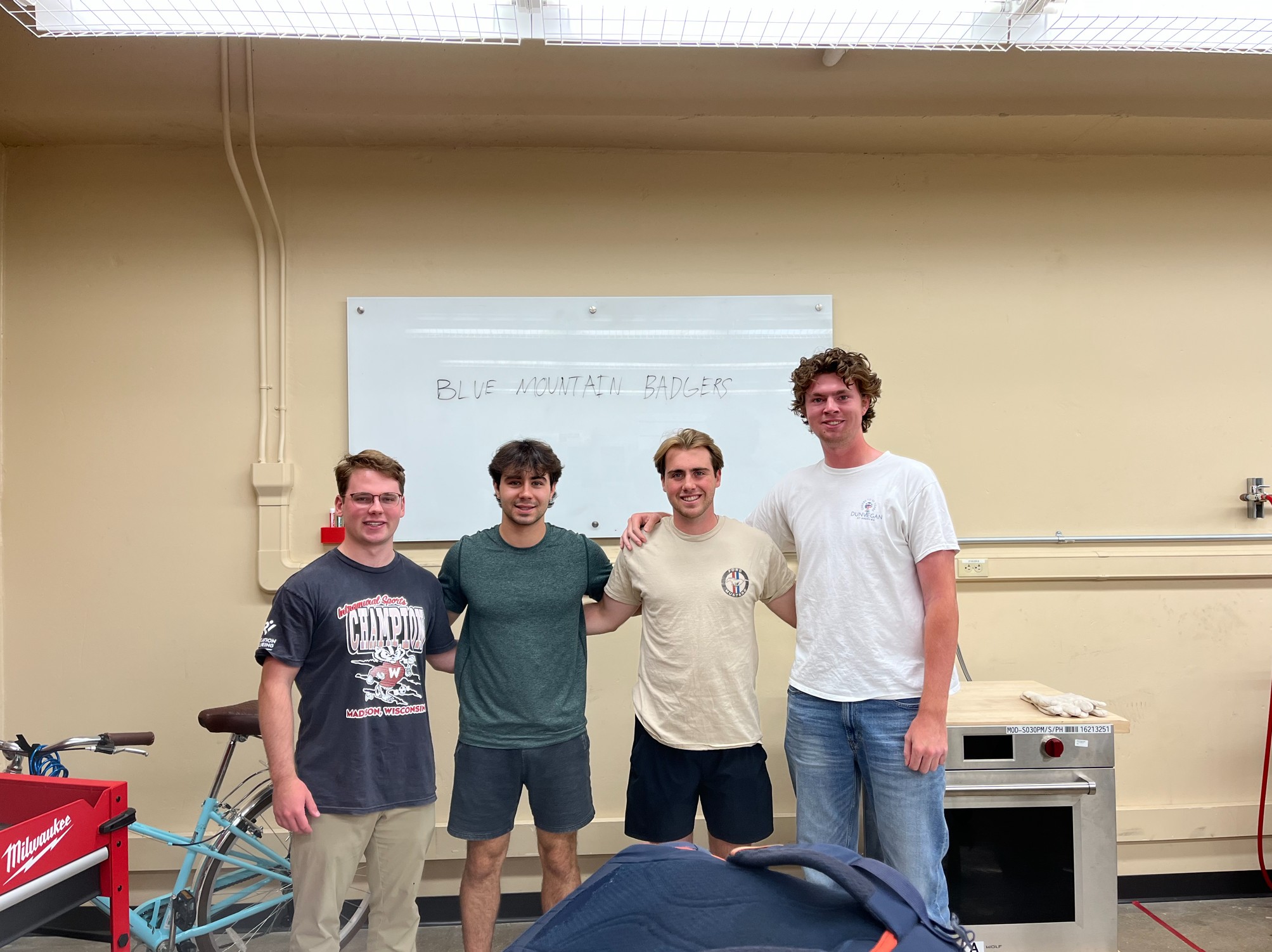

Team members

Connor Wilcox – communicator

Eddie Hanson – admin

Jake Anderson – accountant

Nolan Thompson – facilitator

Client

Charles Ho

Molson Coors